The Virtual Ship

ÅKP and the GCE Blue Maritime members NTNU, VARD, Ulstein and Rolls-Royce Marine has received funding from the Regional Research Central Norway to develop a joint innovation platform, called "The Virtual Ship"

The main objective of the project is to create an "operational virtual ship" based on the work that has been done in the companies and research institutes and gather these into a new joint innovation platform.

Developing an open innovation platform

Historically, the Norwegian maritime industry has been a world leader in the development of innovative and advanced design and technology. This has given the Norwegian maritime cluster's competitiveness and ability to deliver high quality solutions to the high-end shipping market. Innovation speed has been the key. Due to increased awareness of costs and competitors' ability to copy our technology, this position challenged. The need for differentiation and cooperation is becoming increasingly important for the industry to retain its position in the global arena. Access to a shared virtual vessel may be such differentiator and innovation platform.

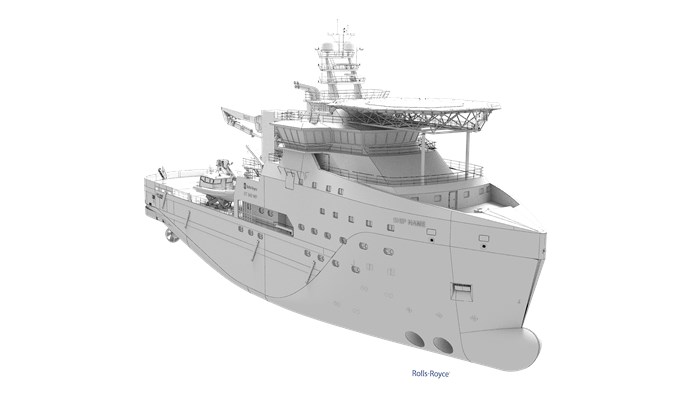

Today, most companies have adopted tools that enables them to produce their components and designs in 3D digital models. However, there are many tools and many formats, some considered "standard", because they have a huge user base, other more proprietary. Only when it is possible to put these together in one complete virtual ship will use this technology really accelerate the digitized innovation and restructuring process in the maritime industry.

The partners in the project have recognized this and is now establishing a common virtual ship project. Through the cluster project GCE Blue Maritime and Blue Innovation Arena will a undergrowth of subcontractors also able to benefit from this, and the great looks that they too will have major benefits in its integration work, while helping to develop subcontracting industry.

Optimizes the design and development process

The concept of a virtual ship is to test ship design, equipment and operations in a controlled environment and optimize the performance of the complete coupled system. Alternatively, one must decoupled system and watch subsystems separately, and then you can lose valuable information. A simulation model can quickly become large and complex, if it should contain everything from hull, weather, waves and deck machinery such as cranes and winches. There are few companies that have the knowledge and resources to create such a complex model.

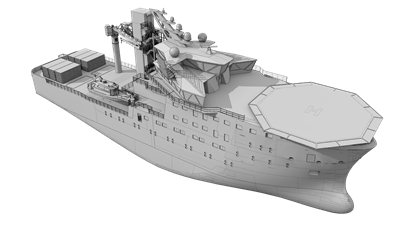

Illustration: VARD Design

Work packages

WP1: Gather partners and various subcontractors to a workshop to develop principles for sharing INFORMATION AND and the legal aspects of the project.

WP2: The technical collaboration platform. Identify and develop user requirements based on open sources and internal knowledge of their partner. Spreading knowledge to SMEs and uncover knowledge gaps

WP3: Based on the requirements specification developing a concept sketch of the virtual ship and develop a technical gap analysis.

WP4: Project and quality management